Designing an optical system for high temperature applications

Few off-the-shelf optical solutions are available for high temperature applications.

Few off-the-shelf optical solutions are available for high temperature applications.

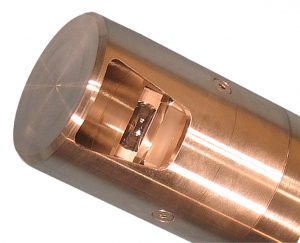

For high temperature applications, optical systems need to be designed to ensure performance is maintained at the application operating temperature. When materials heat up there is expansion. The rate of expansion differs depending on material types. To avoid an optical system going out of focus as it reaches operating temperatures you must take careful consideration of the rate of expansion of components and air spaces. Temperature also affects the refractive index of materials so this also needs to be taken into account in your optical design. To maintain performance over a given temperature range, Resolve Optics designs its high temperature optical systems to be athermal.

Over the last dec ade – Resolve Optics has accumulated the expertise to enable it to design and manufacture specialist optical systems that will effectively operate up to 950°C without the need for additional cooling equipment. This has made it possible for our customers to undertake applications including optical inspection inside an engine or operating furnace as well as non-invasive monitoring of high temperature processes including incineration, recycling, smelting and chemical manufacturing.

ade – Resolve Optics has accumulated the expertise to enable it to design and manufacture specialist optical systems that will effectively operate up to 950°C without the need for additional cooling equipment. This has made it possible for our customers to undertake applications including optical inspection inside an engine or operating furnace as well as non-invasive monitoring of high temperature processes including incineration, recycling, smelting and chemical manufacturing.

If you wish to remotely monitor a hot process safely and wish to discuss a specialist optical system optimised for your high temperature application please contact robwatkinson@resolveoptics.com