ViewPoint

If your Application is subject to thermal variation – should you be considering an athermalised lens ?

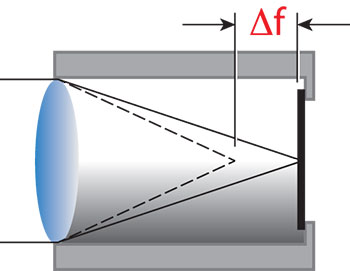

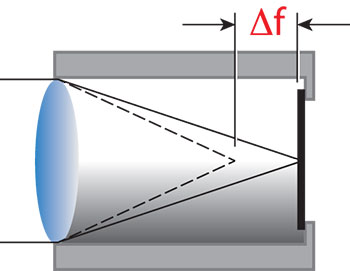

You may be surprised at how quickly some lens designs lose focus with even a 20°C change in temperature. If your application is prone to temperature fluctuations, it is important to develop an optical system that is insensitive to an environment’s thermal change and the resulting system defocus. Developing such an athermal design, which is dependent on the Coefficient of Thermal Expansion (CTE) of the materials and the change in index with temperature (dn/dT), is especially critical in the infrared. The dn/dT of most IR materials is orders of magnitude higher than those of visible glasses, creating large changes in the refractive index. Additionally, while optical systems are often designed in air, the housing material is also sensitive to thermal change, and should be addressed when considering an athermalized design.

There are two forms of lens athermalisation, Passive and Active. Passive Athermalisation of a lens assembly is used when refocusing is not available (no moving parts). By comparison Active Athermalisation allows the lens to be electronically or manually refocused.

Passive athermalization is beneficial in optical systems that are isolated from direct human contact or have limited access to power. Systems that are deployed in space, for example, cannot afford to use the limited battery or solar power to energize motors necessary for maintaining focus. Additionally, motors have limited lifetimes, add weight to launch payloads, and cannot be easily serviced once deployed in space. Therefore, it is undesirable to use them unless absolutely necessary. Hazardous environments can be encountered when performing tasks such as nuclear power plant inspection and border patrol surveillance where temperatures reach extremes that are unsafe for constant human exposure. If the optical system can be passively athermalized, then the available power can be used for transmitting video information or increasing operational time instead of activating motors to maintain focus. To achieve passive athermalization, different temperature-compensating techniques can be customized for all types of optical systems. Optical systems that can be athermalized can consist of reflecting components (mirrors), refracting components (lenses), or a combination of both.

Active athermalisation in its simplest form can be manual adjustment of a lens element or group for refocusing . For more complex optics , such as multi-field-of-view , a procedure can be specified for manual (or motorised) adjustment of several lens elements to maintain focus over a range of magnifications and temperatures. Where automatic active athermalisation is required, a method can be employed that uses a combination of electronics and mechanics . One or more temperature sensors located along the body of the optic feed their signals into an algorithm that calculates the required movement of a compensating lens and then initiates the motion. For simplicity, the compensating lens may be that which already provides close-distance focusing , thus requiring only an increase in the range of movement for athermalization . The location of sensors is especially important for infrared optics and should be dependent on the thermal sensitivity variations within the optical system.

To discuss development of an athermalised lens design to suit your application please contact Resolve Optics on +44-1494-777107 or email markpontin@resolveoptics.com

|